BBR VT CONA CMI internal post-tensioning system

The European assessed CONA® CMI internal bonded or unbonded post-tensioning system is internationally the most up-to-date and advanced multi-strand PT technology, ranging from 1 to 73 strands. It is typically used for bridges (both cast in-situ and precast), LNG/LPG storage, tanks & silos, nuclear power plants and stadiums.

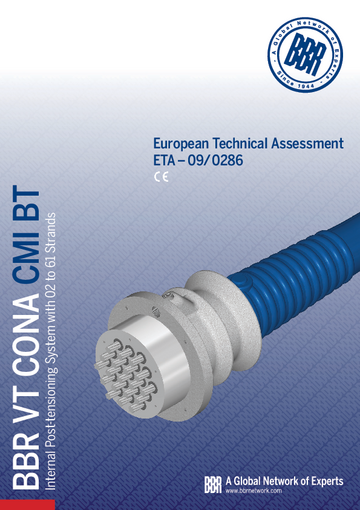

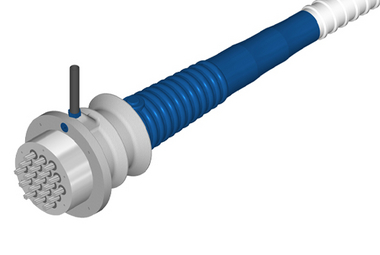

CONA CMI BT

CONA CMI BT

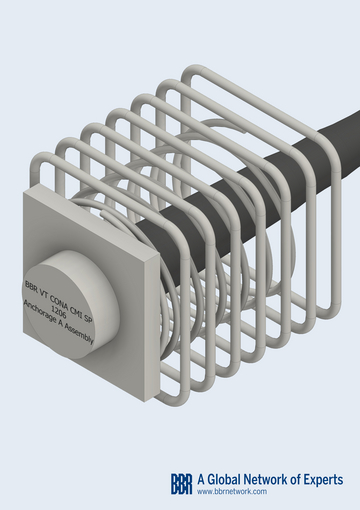

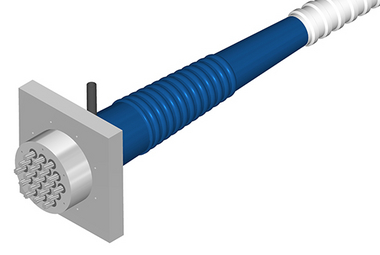

CONA CMI SP

CONA CMI SP

CONA CMI H and K Coupler (fixed & movable)

CONA CMI H and K Coupler (fixed & movable)

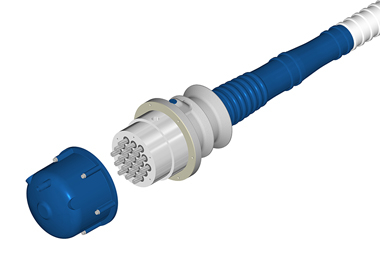

CONA CMI Electrically Isolated Tendons EIT

CONA CMI Electrically Isolated Tendons EIT

Key features

- Standard tendon sizes from 1 to 73 strands, larger sizes on request

- Widest range of tendon sizes with the largest tendon forces available on the international marketplace

- Optimised for 15.7mm diameter, 1,860 MPa strand

- The most compact & light-weight system available utilizing an advanced proprietary load transfer element for very small tendon centre spacings and concrete edge distances at the anchorages

- Application of full post-tensioning force at very low concrete strengths (fcm,0 = 19/23 MPa)

- Fixed and movable couplers for joining tendons

- Corrugated or smooth round tendon duct utilizing either galvanized steel or plastic material

- For bonded applications the ducts are filled with BBR grout

- For unbonded applications the ducts can be injected with grease/wax or circulating dry air. Greased and HDPE sheathed monostrands in grout filled ducts are also possible

- Superior cryogenic performance ideal for LNG tank applications

- Restressable & exchangeable tendons perfectly suited for long-term inspection and maintenance

- Fully encapsulated and electrically isolated tendons offer the highest level of corrosion protection possible

- European Technical Assessment and CE marking

CONA CMI assessment

Download the latest CONA CMI European Technical Assessment.

See our Downloads pageBIM

Download CONA CMI CAD and 3D files

See our BIM page